Total Environment Control

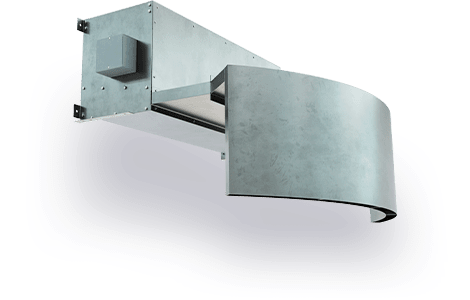

Air Curtains with UV-CWith the onset of Covid-19 and the tremendous increase in curbside pickup, contactless delivery and touchless ordering, restaurants and retailers are searching for ways to safeguard and streamline the process through which food and merchandise are delivered to customers waiting outside in their cars. These businesses are creating or repurposing side doors, dock doors and even customer entry doors so that employees can deliver goods to customers waiting outside the store.

Many of these delivery doors are located in retail areas where climate and insect control are critical. Air curtains are a simple, effective and affordable way to ensure a comfortable interior while further enabling the touchless delivery of goods to customers in the parking lot. Of added benefit, air curtains will help keep energy costs in check by blocking the entrance of unconditioned outside air, reducing the strain and usage of your HVAC system.

-

Select model to view details

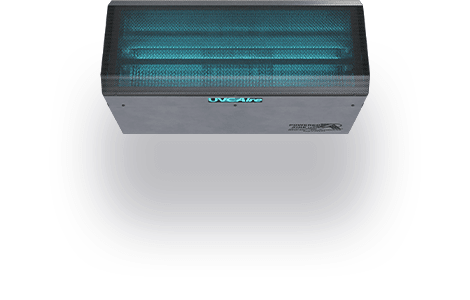

- UVC-Aire