It’s 90 degrees outside and the humidity level isn’t far behind. There’s a heat advisory warning and you can bake cookies on your dashboard. Yet you’re wearing three layers and you can see your breath each time you exhale. If this sounds familiar, there’s a chance you work in cold storage. Few environments create such an abrupt temperature change as cold storage. The constant “go between” from subzero to cold storage to ambient temperatures can create some rather challenging conditions. Unfortunately, they can also be dangerous. Fortunately, there’s a solution.

First, let’s discuss the problems:

Ice, moisture, and fog build-up, especially around high-speed and other types of doors, can create conditions that adversely affect safety, productivity, and performance. Spread these hazards across five, 10 or 20 plus doors and the potential for trouble increases considerably. In this article, we’ll address common problems associated with high-speed and cold storage doors in cooler and freezer environments. We’ll also address how air curtains can help eliminate these hazards.

ICE - If a snow shovel, bucket, and heat gun are part of your regular maintenance, you may have a problem with ice building up on and around your door. We typically see ice buildup in two places. First, when warm air meets the cold door panel, the air releases moisture and condenses. Often, the condensation freezes on the door panel, and in many cases, drips and freezes onto the floor, where people and equipment pass through frequently. Secondly, through normal air density exchange, warm air enters through cold storage doors through the top of the opening. As it enters and hits the cold air, it freezes in places all around the door, including the door header, walls, and nearby product.

In terms of performance, ice can be devastating on a door, causing extensive damage and downtime. Powered Aire’s FAC air curtain includes built-in heaters that can be programmed to cycle on at intervals, helping to dry the condensation and help prevent the accumulation of ice. By managing (and eliminating) ice, you can also eliminate door downtime, helping to keep your door and your workflow moving.

FOG – Ice isn’t the only result of the chilled freezer air meeting the ambient outside air. If a “mini-weather pattern” is created each time the door opens and the resulting front leads to excessive fog build up, there is an increased chance for accidents due to the reduced visibility created by the fog. This can put the people, equipment, and product at risk. By reducing the infiltration of warm air through the top, and sometimes even conditioning the air with heat, air curtains like the Cooler Aire and Freezer Aire can help reduce the presence of fog, increase visibility and create safer cold storage environments.

If you’ve experienced any of these issues while working in cold storage, you’ll be happy to know there’s an easy solution with Air Curtains. As mentioned above, air curtains positioned on the outside of a cold storage doors help prevent the ambient air from mixing the with the chilled air, effectively reducing the ice, fog, and moisture from building up.

Of added benefit, Air Curtains help keep energy costs in check by preventing the ambient air from entering the cooler/freezer, whereby the cooling system will not need to work as hard.

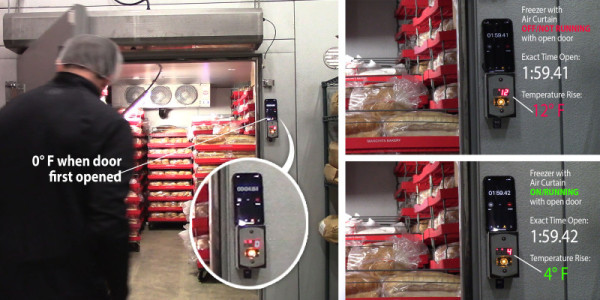

Check out the temperature separation!

It is easy to talk about the benefits of Air Curtains in cold storage. It’s even better when you can see it in action. Powered Aire recently installed an unheated air curtain on a freezer door that struggled with fog and temperature loss each time product was moved in and out. Without the air curtain running, the temperature inside the freezer shot up from 0° to 12° in a two-minute-span. During that same time period, with the air curtain running, the temperature only rose four degrees.