THE SITUATION

If that were the end of the product’s lifecycle, it could be that simple. But there’s a good chance that the product in your freezer has also spent time in a cold storage facility. A hustling, bustling operation that never slows down and has product moving in and out all day.

THE CHALLENGE

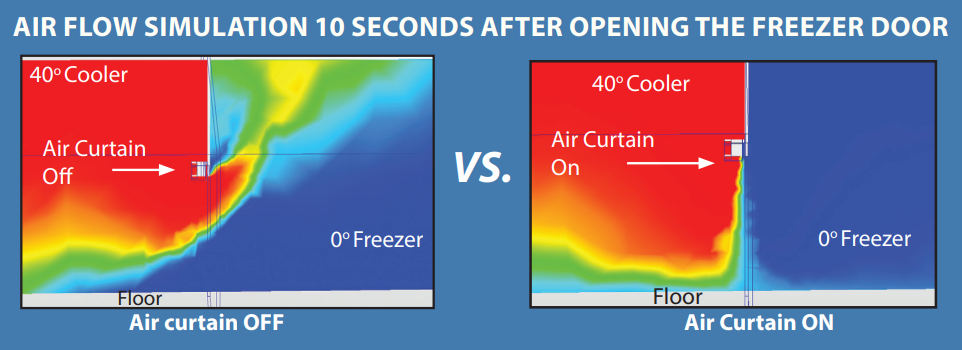

If you’re familiar with Cold Storage operations, you know there is a constant battle against the elements. Each time a door opens, outside air and freezer air clash to create some rather unpleasant conditions. And while open doors mean consistent business, it can also mean water, fog and ice buildup around the doors. These hazards can create unsafe conditions for workers and the equipment passing through. It can also put a strain on the cooling systems and increase the facility’s energy and operational costs.

THE SOLUTION

A simple solution can often be found through the addition of industrial air curtains. Air curtains placed on roll up doors, dock doors and warehouse doors within the cold storage facility are extremely effective ways to eliminate the buildup of ice and fog.

Air Curtains create a thermal barrier of air that prevents the mixing of unconditioned air from the outside with the cold, conditioned interior air. By eliminating the infiltration of the outside air, you also eliminate the buildup of ice and frost. Of added benefit, the air curtain is able to keep the door, and the area around it, dry and, more importantly, your workers safe.