Maintaining consistent temperatures within cold storage environments is vital across industries such as food processing, pharmaceuticals, and logistics. Each time a door opens, warm air infiltrates while chilled air escapes-forcing refrigeration systems to work harder, increasing energy consumption, and impacting product integrity.

Fortunately, there’s an easy way to mitigate these challenges. Powered Aire’s line of cooler and freezer air curtains provides an effective, low-maintenance solution designed to preserve temperatures, protect quality, improve safety and streamline operations in cold storage environments.

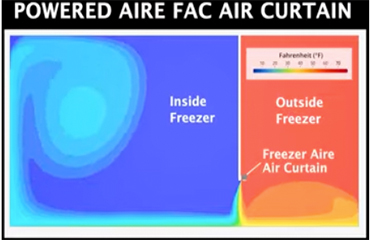

A properly sized and installed air curtain reduces refrigeration load by limiting the exchange of warm and cold air during door openings. By preventing warm, humid air from entering at the top of the doorway and minimizing the escape of cold air at the bottom, air curtains help eliminate humidity-related issues such as fog, frost, and ice buildup. This reduction in temperature loss leads directly to lower compressor run times and measurable energy savings.

THE THREE BIGGEST CHALLENGES IN COLD STORAGE

How does condensation find its way into a freezer? Easy enough. Each time the door opens, the unconditioned outside air rushes in. Once inside, the air (and water) refreezes, placing a layer of ice on all areas it’s touched. Fog and moisture on and around the door are also common challenges that can be remedied by using an air curtain.

A key benefit of cold storage air curtains is their ability to reduce the buildup of ice, fog and moisture, which can be detrimental to efficiency in cold storage settings. Without an air curtain, the entrance of warm outside air allows for moisture to build up, which can result in:

- Products enveloped in ice

- A layer of fog that decreases both visibility and worker safety

- Roll-up doors that need to be routinely serviced to remove ice, causing operational downtime

- Frozen floors that can be dangerous for workers

- Decreased efficiency due to challenging work conditions

From an equipment protection standpoint, air curtains safeguard door investments by reducing condensation, preventing ice accumulation, and avoiding frozen seals. This not only extends the lifespan of doors but also minimizes downtime and maintenance costs.

Air curtains also contribute to workplace safety by keeping floors around cooler and freezer entrances free from moisture and ice, reducing slip hazards and supporting a safer, more productive work environment.

Air curtains are essential for maintaining food safety, product quality, and shelf life. They enable products to move seamlessly between loading docks, freezers, and coolers without compromising temperature stability. By retaining conditioned air and controlling airflow during product transport, facilities can operate more efficiently while ensuring consistent product standards.

Powered Aire’s Cold Storage Air Curtains offer measurable benefits in energy efficiency, sustainability, and performance. To learn more, check this out: https://poweredaire.com/air-curtain/commercial/cold-storage